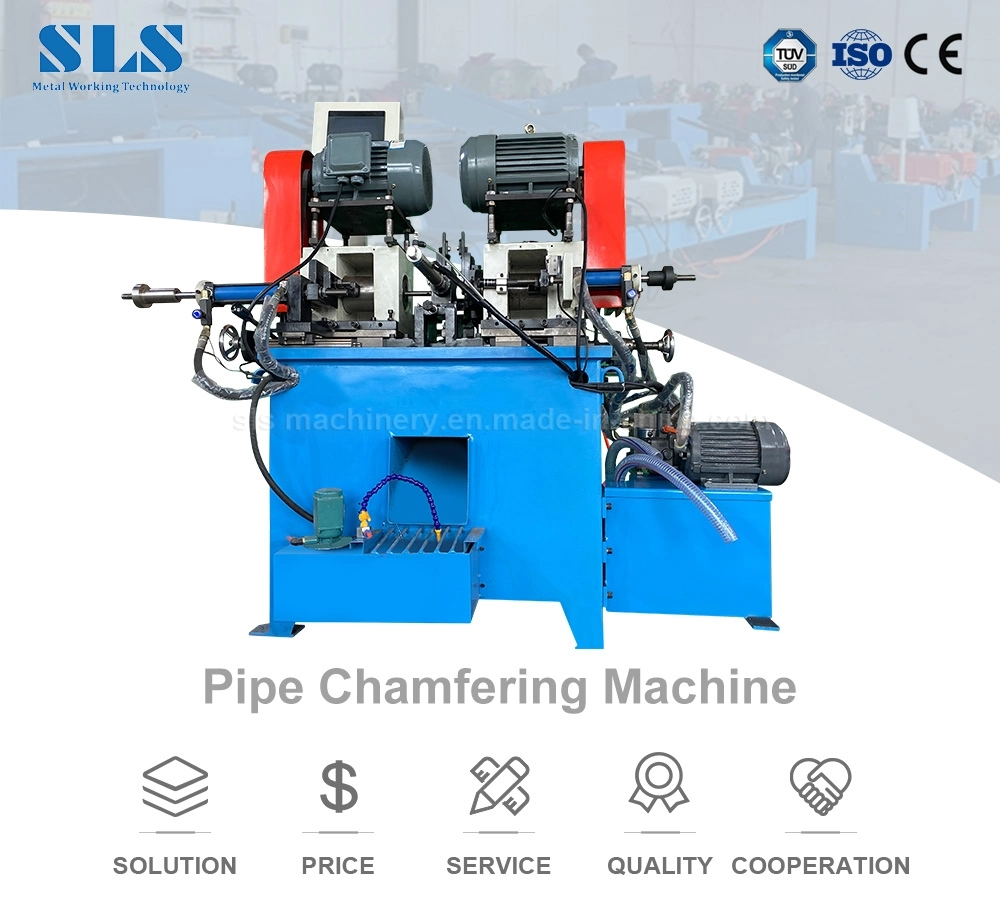

Angle Adjustable Air Operated Smoothing Tube Bar Double End Pipe Deburring Automatic Chamfering Machine

Description

Basic Info.

| Model NO. | DEF-60Y |

| Applicable Material | Ms.Ss,Copper,Aluminum |

| Accuracy | +/- 0.1mm |

| Chamfering Head | Double Head Chamfering |

| Company Type | Factory |

| Chamfering | by Mechanical |

| Driven | Hydraulic+Mechanical |

| Knife | Alloy Steel Knife |

| Technical | Cold Chamfering |

| Chamfering Sides | 1/2/3 Sides |

| Name | Automatic Chamfering Machine |

| Controlling | Hydraulic |

| Applicable Shape | Round or Other Shapes |

| Transport Package | Wooden Case Packing |

| Specification | Max. 60mm |

| Trademark | SZ-SLS |

| Origin | China |

| HS Code | 846190 |

| Production Capacity | 500 Pieces/Year |

Product Description

Brief Introduction on Automatic Chamfering Machine

SLS Double Head Chamfering Machine also know as double head pipe beveling machine is a special kind of pipe end smooth machine.It is a kind of semi-automatic machine with manual loading,automatic feeding,automatic mechanical chamfering and automatic clamping driven by hydraulic.Chamfering process can be finished at one time in fast speed and accurate chamfering requirement. Clamp device andknife holder are precisely designed for ensure the center line between work-piece and knife holder at the same level. Double headschamfering together greatly increase the productivity.We keep many chamfering machines in stock for quick shipments.

Features on Automatic Chamfering Machine

A circular tube modifies an interior angle,an external angle and flat plane at one time with fastness and precision.

Automatic and manual working mode which are convenient for adjusting the machine,mold and chamfering knife.

Material Available: Carbon Steel,Stainless Steel,Copper,Aluminum...

Each process of chamfering work is driven by hydraulic.

Clamp device and knife holder are precisely designed for ensure the center line between workpiece and knife holder at the same level.

Double head chamfering working simultaneously for guarantee high quality chamfering

Dual Feed Chamfer system:

First speed------Fast forward movement nearly to tube end to save the time.

Second speed---Infinitely variable forward adjustable Chamfering speed to get smooth finish.

Good mechanical parts ensure machine runs in high stability.

Main Technical Parameters Sheet

| Model | DEF-50AC | DEF-80AC | DEF-120AC | DEF-60Y |

| Max. Chamfering Capacity | ¢50mm | ¢80mm | ¢120mm | ¢60mm |

| Chamfering Angle | 30°/60°/45°... | 30°/60°/45°... | 30°/60°/45°... | 30°/60°/45°... |

| Motor Power | 1.5Kwx2 | 2.2Kwx2 | 3.0Kwx2 | 2.2Kwx2 |

| Pressure | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa |

| Knife | Mitsubishi | Mitsubishi | Mitsubishi | Mitsubishi |

FAQ:

| 1 Q: Are you a manufacturer or trading company? | A: Yes, we are a manufacturer.We are focusing on metal pipe/tube processing machines production. |

| 2 Q:Where is the nearest airport to your company? | A: Wuxi Airport or Shanghai Airport. |

| 3 Q: How to choose the pipe/tube chamfering machines? | A: You have to inform us following details:- Pipe Outdiameter Range- Wall Thickness Range- The Pipe Material- Chamfering Angle- Chamfering Length- Tube Original Length- Which Sides Need Do Chamfering |

| 4. Q: Do you have CE certificate? | A: We have CE certificate. |

| 5. Q:How about your service? | A: Before Sales Serive: 1. We will help our customer confirm the right model according to the offered pipe inforamtion.2. Welcome to visit our factory to see our machine and our workshop before you place an order. After Sales Service:1. We provide manual book,detailed machine installation,commissioning video for help you correctly operate machine.2. We provide free installation,commissioning and training at our factory.If you need engineer go to your factory for machine installation, air tickets,food,hotel, local transportation shoule be at your account.3. Any problems on machine,we will reply you by email/tel or other online contact within 24 hours. |

Prev: Semi

Our Contact